Key Specifications / Features

Model No.: Hits: 49

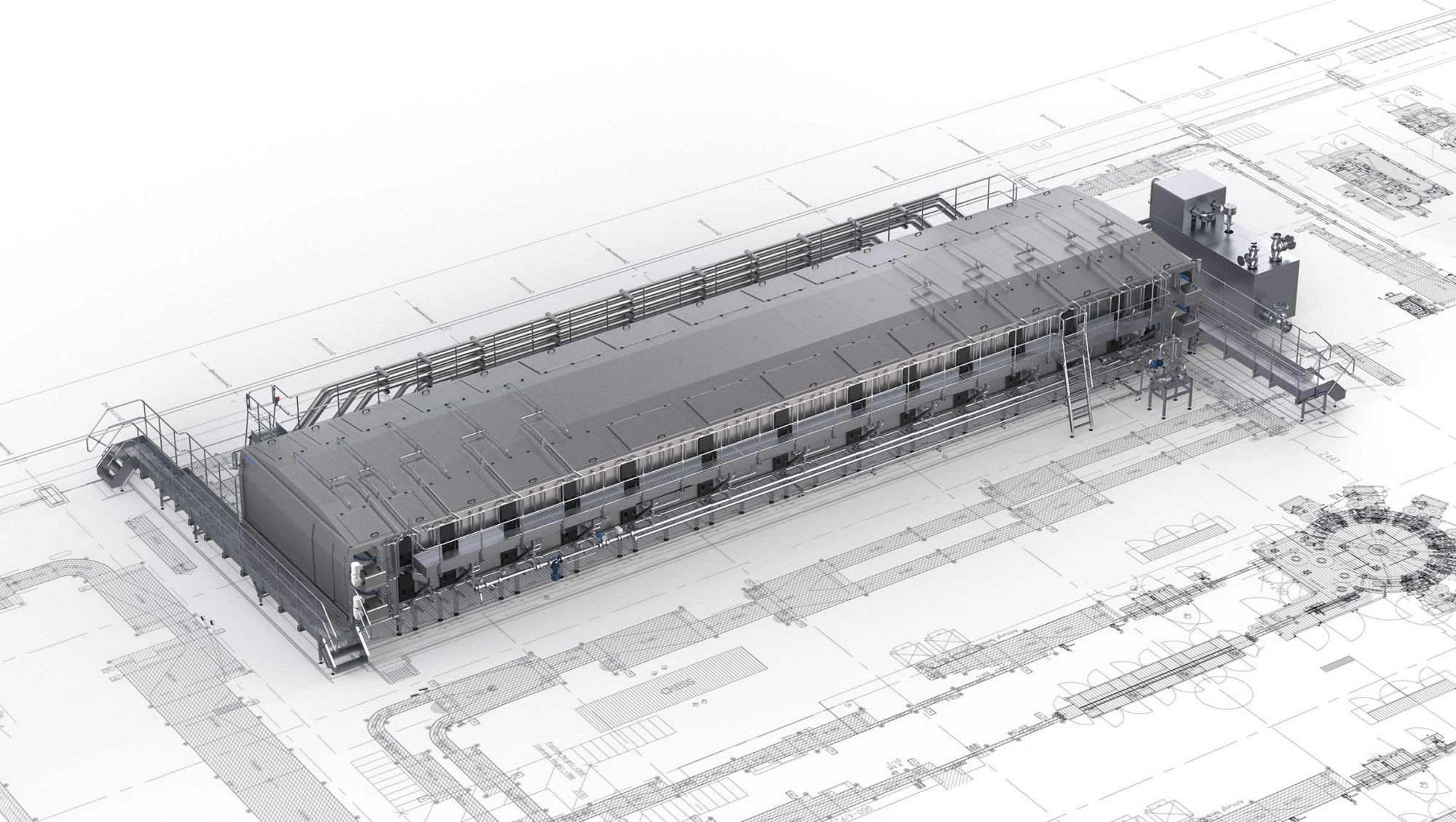

Modular Tunnel Pasteuriser Provider: Single-deck or Double-deck Tunnel Pasteuriser with PU Control System, Fully Automatic Product Change-over.

Request a quoteTags

Detail Information

Product safety is a core issue in marketing your beverage. Pasteurization is very often procedure number one when it comes to preservation of the just filled products. The LinaFlex tunnel pasteurizer offers a pasteurization process with precise PU control and efficient use of resources. You will get a pasteurizer that is specifically designed to meet your operational requirements.

At a glance

- Modular single-deck or double-deck tunnel pasteurizer with precise PU control system

- Main conveyors are exactly adjusted to suit the container characteristics and production conditions

- Quick installation

- Integration of long-lasting components

Options for interior cleaning

| Feature/Machine variant | LinaFlex | LinaFlex Pro | LinaFlex Pro with a CLEAR system |

| Boil out | ✓ | ✓ | ✓ |

| Detachable double sieves | ✓ | X | X |

| Dosing system | ✓ | ✓ | optional |

| Sedimentation | X | ✓ | ✓ |

| Filtration | X | ✓ | ✓ |

| UV water treatment system | X | X | ✓ |

The concept

- Pasteurizer in modular basic design

- Integration of all basic components such as PUC³, Marathon Belt, or Ironman Belt

- Boil out of the housing and manual cleaning procedures

- Removal of particles and dirt using detachable double sieves

- Manual cleaning of the detachable sieves

- Regular water changes

- Use of chemical disinfectants

- Automatic removal system for glass fragments and other particles

- Individual pasteurizer configuration with the desired components

- Optional: Retrofitting option for the CLEAR system

- Reliable extraction and removal of particles

- Reliable protection of the nozzle system against clogging

- No manual cleaning of detachable sieves is necessary

- Better removal capacity as compared to filter conveyor systems

- Optimized water volumes thanks to integrated zone tanks

- Up to 20 % reduced energy consumption during heating

- Low consumption of chemicals and energy

- The drive output per deck is 0.75 kW

- Full insulation as an option for a reduction in emission losses of up to 60 %